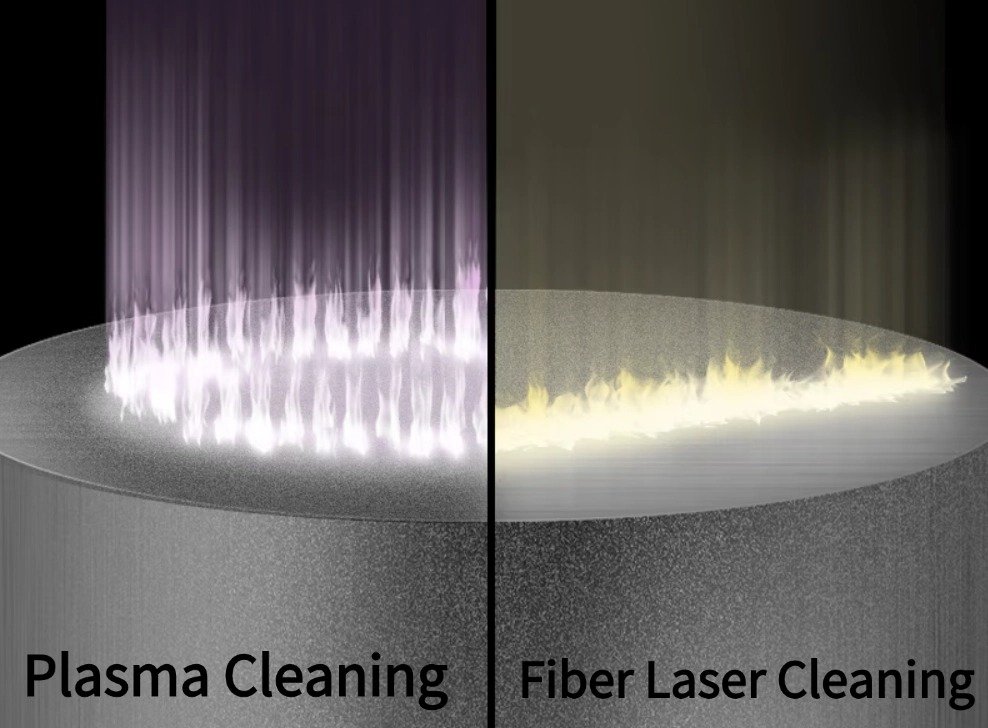

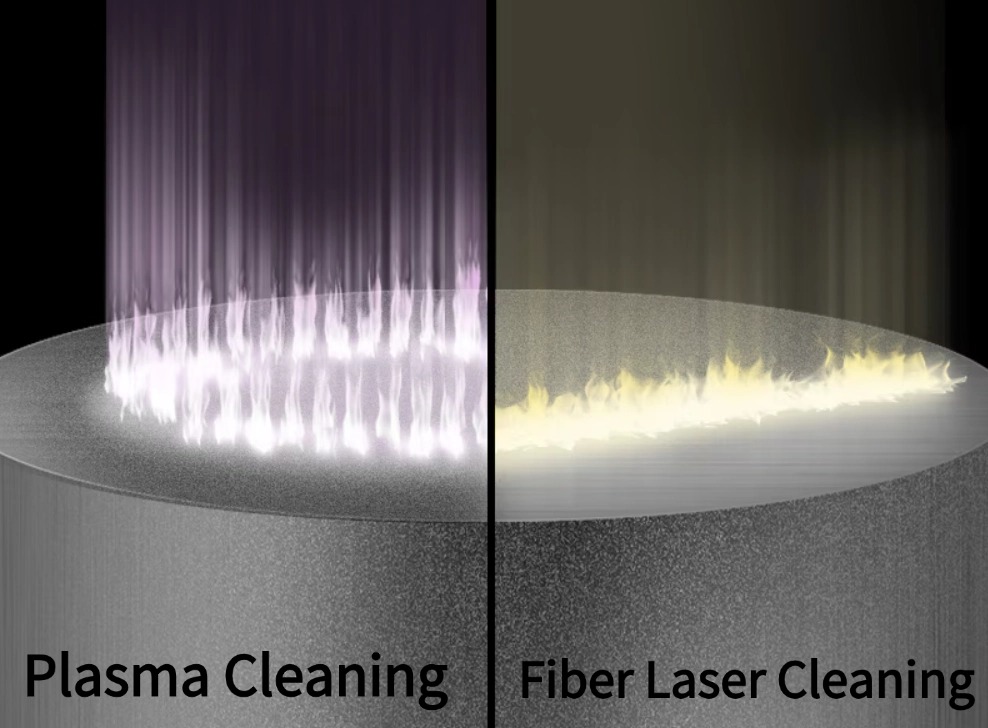

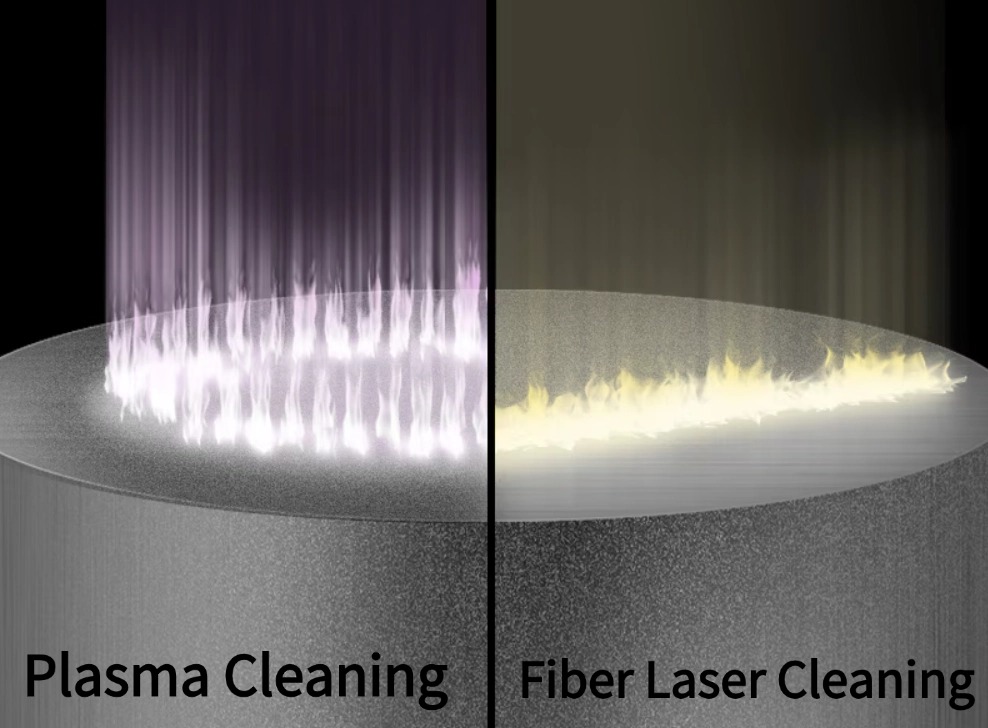

Choosing the right technology for industrial cleaning can save costs and boost efficiency! Both fiber laser cleaning and plasma cleaning are mainstream eco-friendly solutions today, but their applicable scenarios differ greatly— the former excels at fast decontamination of metal surfaces, while the latter specializes in molecular-level precision cleaning. Many enterprises struggle between the two; in fact, the core depends on your cleaning needs: do you pursue large-area efficient processing or require nano-level cleanliness? This article breaks down their core differences in plain language to help you quickly lock in the optimal solution!

I. Core Differences at a Glance: Distinguish Key Contrasts in One Table

| Comparison Dimension |

Fiber Laser Cleaning |

Plasma Cleaning |

| Core Principle |

Laser pulses vaporize contaminants (non-contact) |

Ionized gas chemical reaction + physical sputtering for decontamination |

| Processing Speed |

Extremely fast (5-25 ㎡/hour for metal rust removal) |

Relatively slow (atmospheric type line speed 0.1-2m/s; vacuum type has cycle time) |

| Cost Investment |

Starts at $4,600, electricity-only, zero consumables |

High initial investment, requires gas and energy, medium-high operating costs |

| Environmental Performance |

Zero pollution, zero waste, no exhaust gas treatment needed |

Exhaust gas management required, by-products mainly gas |

| Core Advantages |

Large-area processing, high efficiency, no substrate damage |

Molecular-level cleaning, surface activation, suitable for heat-sensitive materials |

II. Core Highlights of Two Technologies: Each Has Its Strengths

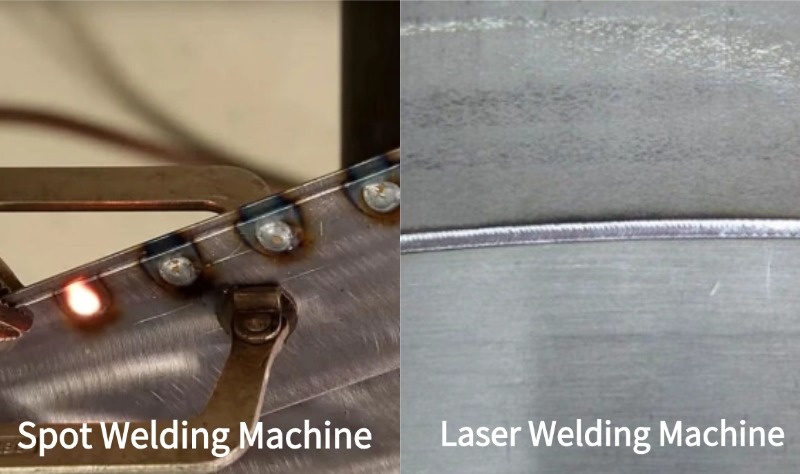

1. Fiber Laser Cleaning: The "Efficiency King" for Metal Cleaning

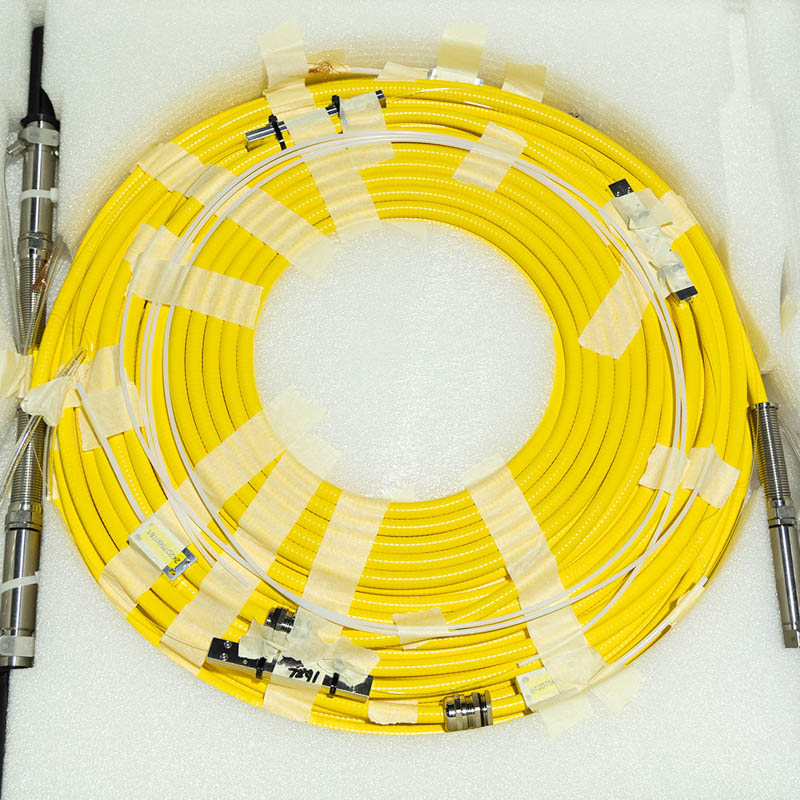

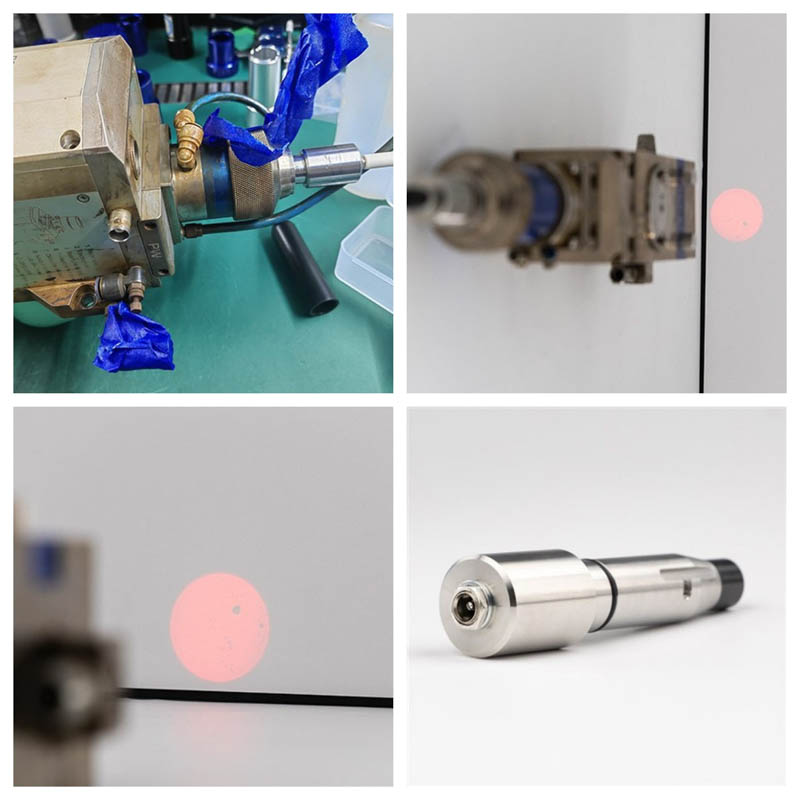

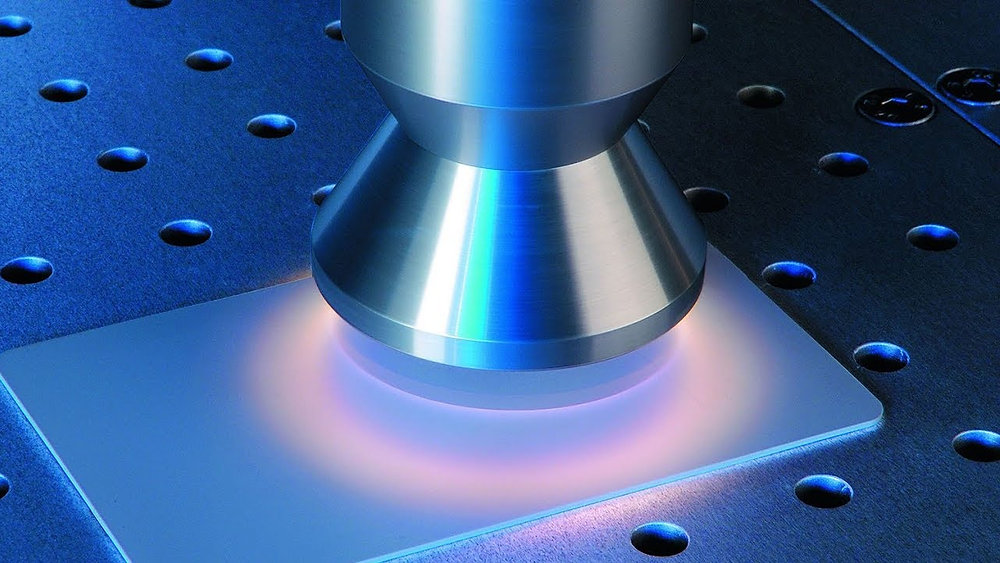

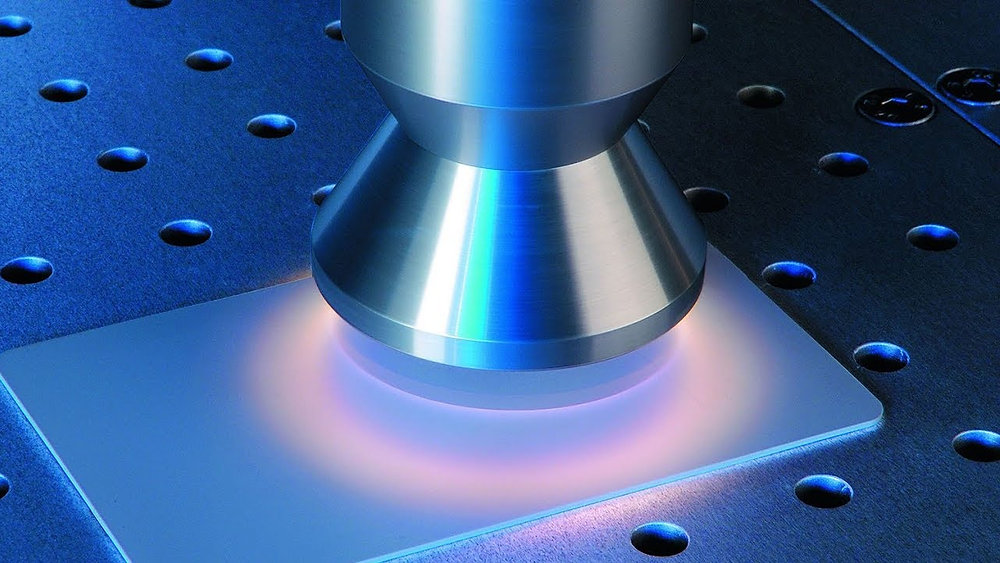

As a non-contact technology, it uses nanosecond pulsed lasers with a wavelength of 1064nm to precisely target contaminants such as rust and paint (contaminants absorb energy more easily than metals) and instantly vaporize them. Its advantages are particularly prominent:

- Fast speed: Processes paint at 10-20 ㎡/hour and thick rust at 5-10 ㎡/hour, the first choice for large-area cleaning in heavy industry;

- Low cost: Only consumes electricity, no chemical solvents, abrasive media or other consumables, extremely cost-effective for long-term use;

- High precision: The laser spot can be focused to 10-200μm, enabling selective cleaning of specific areas without damaging the substrate, and supporting automated integration;

- Wide application: Suitable for automotive manufacturing, shipbuilding, aerospace, cultural heritage restoration and other fields, especially for metal surface pretreatment.

2. Plasma Cleaning: The "Detail Expert" for Precision Cleaning

It activates gases such as oxygen and argon through radio frequency power to form ionized plasma, decomposing organic contaminants through chemical reactions and removing tiny particles through physical sputtering. Its highlights focus on precision scenarios:

- Ultra-clean cleaning: Can remove ultra-thin organic films and nano-scale particles, meeting the high cleanliness requirements of semiconductors and medical devices;

- Surface activation: Can improve material surface energy, increasing the adhesion of coatings and adhesives by 200-400%;

- Suitable for complex structures: Gas can penetrate microholes and deep into 3D structures, treating dead corners inaccessible to lasers;

- Low-temperature safety: The substrate temperature does not exceed 80-100°C, suitable for heat-sensitive materials such as plastics and electronic components.

III. Selection Guide: Match Your Needs

Choose Fiber Laser Cleaning if You:

- Mainly clean thick-layer contaminants such as rust, paint and scale on metal surfaces;

- Pursue high-speed, large-area processing and need to integrate into production line automation;

- Value low-cost operation and do not want to bear the costs of consumables and waste disposal.

Choose Plasma Cleaning if You:

- Need to handle molecular-level residues in semiconductors, precision electronics, medical devices, etc.;

- Need to clean complex 3D structures and microholes, or require simultaneous surface activation;

- The cleaning objects are heat-sensitive materials such as plastics and polymers that cannot withstand high temperatures.

Conclusion

There is no absolute superiority between fiber laser cleaning and plasma cleaning; the key lies in scenario adaptation: for large-area efficient decontamination of metals, fiber laser cleaning is definitely the right choice; for molecular-level cleaning and surface activation in precision industries, plasma cleaning is more reliable. If your demand is industrial metal surface cleaning and you want to balance efficiency, cost and environmental protection, fiber laser cleaning is undoubtedly a more cost-effective option.