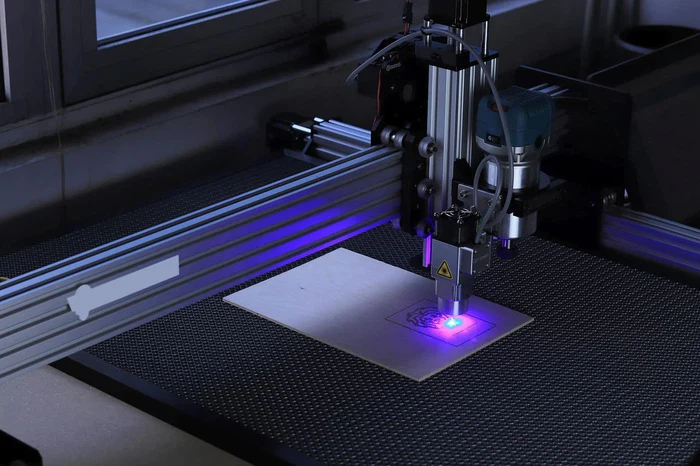

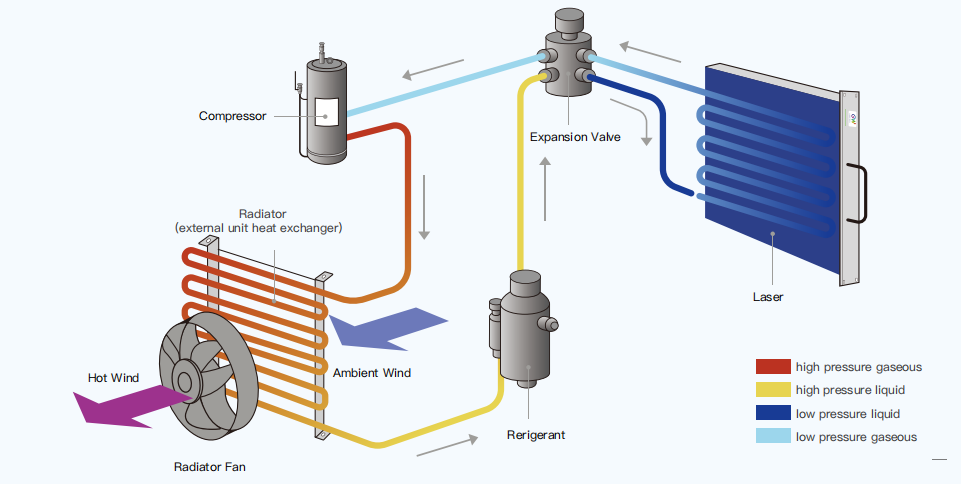

New users are often overwhelmed by the dense parameter options of laser marking machines? There's no need to fixate on "magic numbers"-the core lies in mastering the coordination logic of three key parameters: power, speed, and frequency. They're like heat, cooking time, and seasoning in cooking-only precise matching can achieve ideal marking results. Based on a 50W laser, this guide breaks down parameter principles, material adaptation schemes, and testing methods, helping you quickly transform from a novice to a skilled operator (parameters for non-50W models can be converted proportionally).

I. Decoding Core Parameters: It's Not Just "Twisting Knobs," But an Energy Balance Art

Laser marking essentially involves the interaction between energy and materials. The core of parameter setting is controlling the "total energy input per unit area"-jointly determined by power (energy intensity), speed (exposure time), and frequency (pulse density). These three parameters are dynamically linked and mutually influential, rather than being adjusted independently.

1. Power: The "Energy Intensity" of the Laser

Power, measured in watts (W), directly determines the peak energy output of the laser beam, equivalent to the "strength" of marking. Higher power means more energy transferred to the material per unit time, resulting in more pronounced processing effects.

Low power (5-15W): Suitable for surface marking with extremely shallow depth (0.01-0.05mm), such as black annealing on stainless steel and frosted white marking on anodized aluminum, only changing the surface state without damaging the substrate.

Medium power (15-30W): The most versatile parameter range for standard engraving (0.05-0.2mm depth), compatible with most plastics, wood, and coated metals.

High power (30-50W): Designed for deep engraving (>0.2mm, up to 0.3-1.0mm+) or cutting needs, such as tactile engraving on aluminum and deep marking on molds. Avoid excessive energy to prevent material melting.

2. Speed: The "Controller" of Exposure Time

Speed, measured in millimeters per second (mm/s), controls the movement speed of the laser head and indirectly determines the material's exposure time-the slower the speed, the longer the laser stays, and the more energy accumulates; the faster the speed, the shorter the exposure time, and the shallower the energy effect.

Low speed (50-200mm/s): Used for deep engraving, cutting, or high-contrast marking (e.g., black annealing on stainless steel), maximizing energy input to form obvious depth or color changes.

Medium speed (200-600mm/s): A universal gear balancing quality and efficiency, suitable for regular engraving on metals and wood. Novices can start with this range.

High speed (600-1200+mm/s): Targeted for surface marking, such as clear engraving on plastics and film removal on coated metals, reducing heat conduction to avoid material melting or burning.

3. Depth: The "Natural Result" of Energy Input

Depth refers to the vertical displacement after marking (in mm) and is not a directly set parameter, but a combined result of power, speed, and processing times-the higher the total energy input, the deeper the depth (or more obvious the color change).

Surface annealing (0-0.01mm): Only produces color change through oxidation without substantial depth, e.g., black marking on stainless steel.

Shallow engraving (0.01-0.1mm): Removes the surface material to form a slight tactile feel, e.g., white marking on anodized aluminum.

Standard engraving (0.1-0.3mm): Clear and distinguishable, suitable for serial numbers and logo marking, with the widest application.

Deep engraving (0.3-1.0mm+): Used for scenarios requiring a strong tactile feel such as molds and stamping parts, requiring multiple processing to accumulate energy.

4. Frequency: The "Regulator" of Pulse Density

Frequency, measured in kilohertz (kHz), represents the number of laser pulses per second, determining pulse overlap and serving as a key parameter to auxiliary optimize effects.

High frequency (50-100kHz): Short pulse intervals for smooth and continuous heating, suitable for black annealing on stainless steel and coating stripping, enabling uniform, particle-free marking.

Medium frequency (20-60kHz): The most versatile, balancing smoothness and efficiency, applicable to most regular engraving (plastics, wood, metals).

Low frequency (<20kHz): Long pulse intervals for dot-like effects, suitable for textured marking on plastics or cutting scenarios requiring reduced heat input.

II. Material-Effect Adaptation Table: A "Quick Reference" for Direct Application

The following parameters are formulated based on a 50W laser. Always test with scrap materials before actual operation (material batches and surface conditions can affect results). For non-50W models, calculate the starting value by "target power/50W × maximum power of your machine."

| Material Type |

Target Effect |

Power (W) |

Speed (mm/s) |

Key Notes |

| Stainless Steel |

Black annealing (high wear resistance) |

35-45 |

100-300 |

Use high frequency (50-80kHz) for color development via oxidation |

| Stainless Steel |

Shallow engraving (no melting) |

10-20 |

500-1000 |

High speed + low power to avoid deep melting |

| Anodized Aluminum |

White marking (color layer removal) |

15-30 |

500-800 |

Precisely remove the anodized layer without damaging aluminum |

| Raw Aluminum |

Dark engraving |

40-50 |

200-400 |

1-2 repeated passes to enhance effect |

| Plastics (ABS/Acrylic) |

Clear engraving (no melted edges) |

7.5-15 |

700-1200 |

High speed + low power to prevent material melting |

| Hard Wood |

Dark engraving (carbonization) |

25-40 |

200-400 |

Use thermal action for natural carbonization and enhanced contrast |

| Coated Metals |

Coating stripping |

10-25 |

400-700 |

Act only on the coating to avoid substrate damage |

| Glass/Ceramics |

Frosted etching |

5-15 |

300-600 |

Multiple passes for uniform frosted effect |

III. Scenario-Specific Parameter Strategies: Targeted Optimization for Doubled Effects

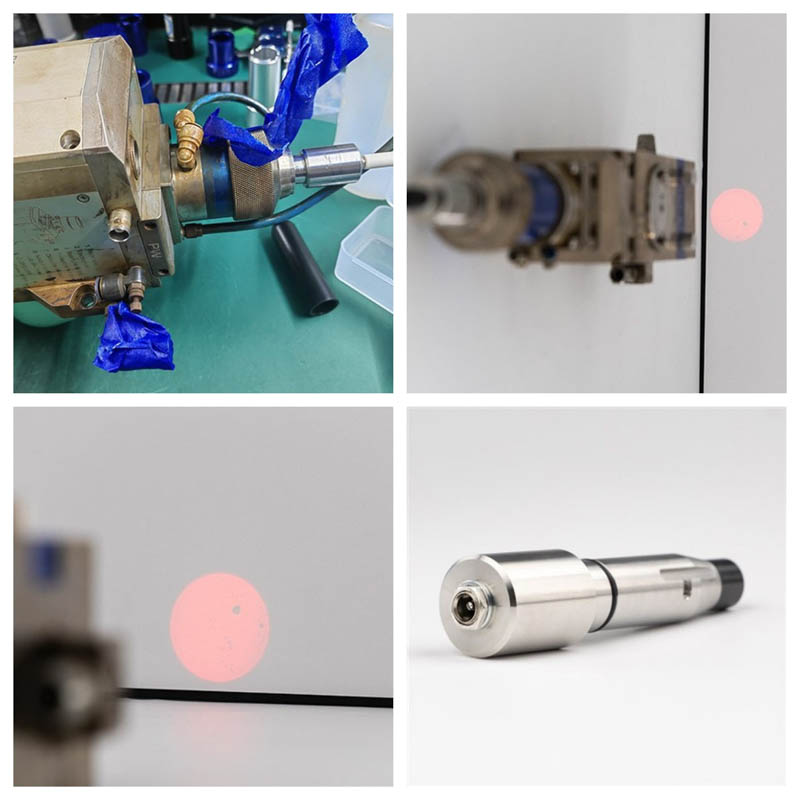

1. Black Annealing on Stainless Steel: The Key to Wear-Resistant, High-Contrast Marks

The goal is to form a uniform dark iron oxide layer without obvious depth. The parameter core is "stable heating"-power 35-45W (medium-high to meet oxidation threshold), speed 100-300mm/s (slow to accumulate heat), frequency 50-80kHz (high frequency for uniform heating). Too low power or too high speed will result in gray marks instead of pure black.

2. White Marking on Anodized Aluminum: Precise Layer Removal Without Damage

The aim is to cleanly remove the colored anodized layer to expose the bright metal underneath, forming a clean white mark. The key is "precise energy control"-power 15-30W (medium power just enough to vaporize the coating), speed 500-800mm/s (medium-high speed for clean removal and high throughput), frequency 20-50kHz (medium frequency for clean material removal). Excessive power will burn the aluminum, while insufficient power fails to completely remove the layer.

3. Plastic Engraving: The Secret to Clear, Melt-Free Details

The core is "rapid vaporization to minimize heat diffusion to surrounding areas"-power 7.5-15W (low power just enough to reach the material's vaporization point), speed 700-1200mm/s (the most critical setting to limit exposure time and prevent melting), frequency 40-60kHz (medium-high frequency to enhance line sharpness). Speed is crucial-slower speeds cause edge melting and clumping, affecting details.

4. Hard Wood Engraving: Textured Natural Carbonization

Use laser heat to carbonize wood fibers for deep brown or black engraved patterns with good contrast and three-dimensionality. Parameter matching: power 25-40W (medium-high to achieve carbonization and gentle material removal), speed 200-400mm/s (slow to medium to ensure effective carbonization and material removal). 1-2 repeated passes can deepen the mark and color.

5. Coated Metal Film Stripping: Precise Stripping Without Corrosion

The goal is to cleanly remove paint or powder coating to expose the bare metal substrate without damage. The key is the "peeling effect"-laser energy vaporizes the coating at the interface to make it peel off. Parameters: power 10-25W (low-medium, carefully calibrated based on coating thickness and type), speed 400-700mm/s (medium to balance effective removal and control), frequency 50-100kHz (high frequency to thoroughly break the coating bond). Precise power calibration is critical to avoid corroding the underlying metal.

IV. Parameter Conversion + Testing Methods: Avoid Waste and Quickly Find Optimal Settings

1. Parameter Conversion for Non-50W Models

If your laser's power is not 50W, calculate the starting value using a "proportional coefficient": Proportional coefficient = target power (based on 50W) ÷ 50W × maximum power of your machine.

Example 1: A 30W machine aiming for 40W black annealing on stainless steel (50W benchmark) → 30W × (40÷50) = 24W, start testing from 24W.

Example 2: A 100W machine aiming for 30W plastic engraving (50W benchmark) → 100W × (30÷50) = 60W, start from 60W.Note: After conversion, start testing from a lower value and gradually adjust upward to avoid excessive energy.

2. Grid Testing Method: The Fastest Way to Find Optimal Parameters

Blindly testing parameters wastes materials-the "grid testing method" is an efficient solution:

Prepare scrap materials: Use the same material as the final product to avoid deviations caused by material differences.

Design a grid: In your software, create a matrix of small squares (e.g., 5×5mm) with the number adjusted based on the parameter range.

Single-variable testing: Fix speed and frequency first, program each square to run at different power levels (e.g., 20W, 25W, 30W…), and observe the results after running.

Evaluate and screen: Identify the power value with the best effect, then fix power and frequency to test different speeds in a new grid, ultimately determining the optimal combination.

Conclusion

There's no "one-size-fits-all" solution for laser marking parameter settings. The core is understanding the "energy balance" logic and making targeted adjustments based on material characteristics. Start with the basic parameter principles and adaptation tables in this guide, and accumulate experience through grid testing-you'll soon master the marking skills for different materials. If you need personalized parameter schemes for specific materials (e.g., special plastics, alloys) or effects (e.g., ultra-fine textures, ultra-deep engraving, feel free to contact professional teams for customized guidance to maximize the potential of your laser marking machine.