High-power fiber lasers are transforming industries with their high efficiency, excellent beam quality, and compact structure. But as laser power increases, so does the heat generated within the fiber core—posing serious challenges to performance and reliability.

This article explores the cutting-edge research on fiber core temperature characteristics in high-power fiber lasers. Based on the doctoral work of Lou Zhaokai at the National University of Defense Technology, the findings help guide thermal management and improve laser output quality.

Why Temperature Matters in Fiber Lasers

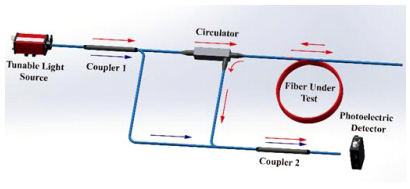

With the commercialization of single-fiber lasers exceeding 10 kW, the thermal load inside the fiber core has become a limiting factor. High temperatures can degrade splicing quality, distort beam properties, and trigger transverse mode instability (TMI)—a known enemy of stable, high-power operation.

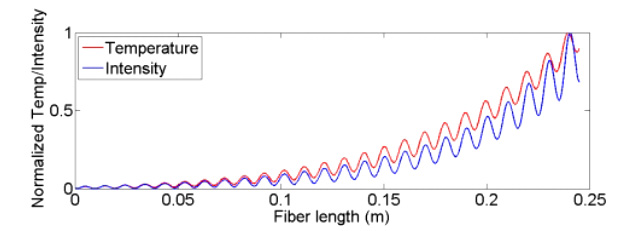

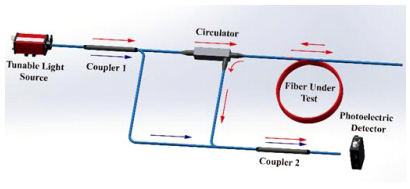

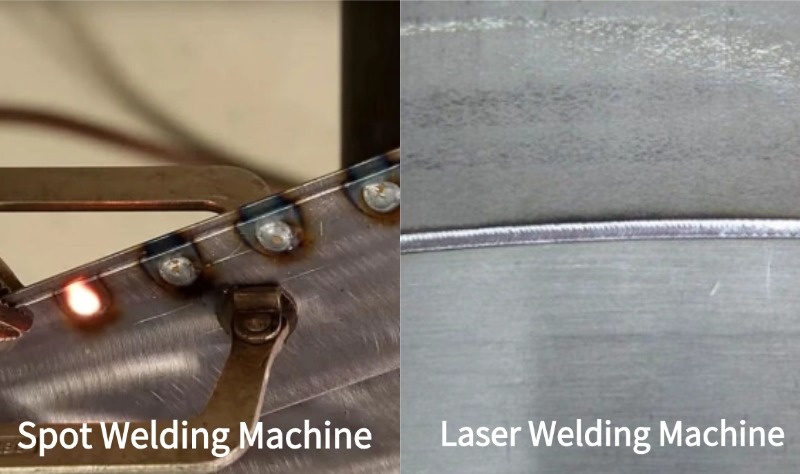

Image 1: Temperature distribution along the fiber core and mode intensity distribution when mode instability occurs

Innovations in Temperature Measurement

A key contribution of this research is a systematic, online method for measuring fiber core temperature using optical frequency domain reflectometry (OFDR). This method provides:

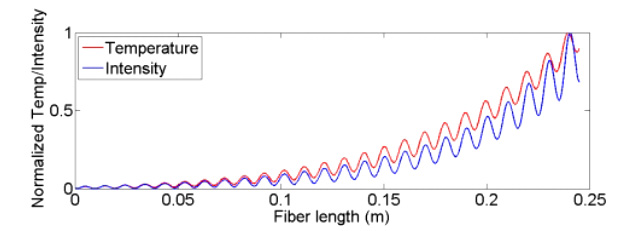

Image 2: Schematic diagram of the basic structure of the Mach-Zehnder interferometer

Key Findings

1. Temperature Distribution Trends

-

In oscillators: The highest temperature occurs at the splice point between the gain fiber and high-reflection grating.

-

In amplifiers: The temperature rises then falls along the pump injection direction, showing a non-uniform thermal profile.

2. Pump Schemes and Thermal Effects

-

Tandem pumping generates lower peak temperatures and a more even heat distribution compared to traditional semiconductor end-pumping.

-

Distributed side-pumping helps balance quantum loss heat, easing thermal stress.

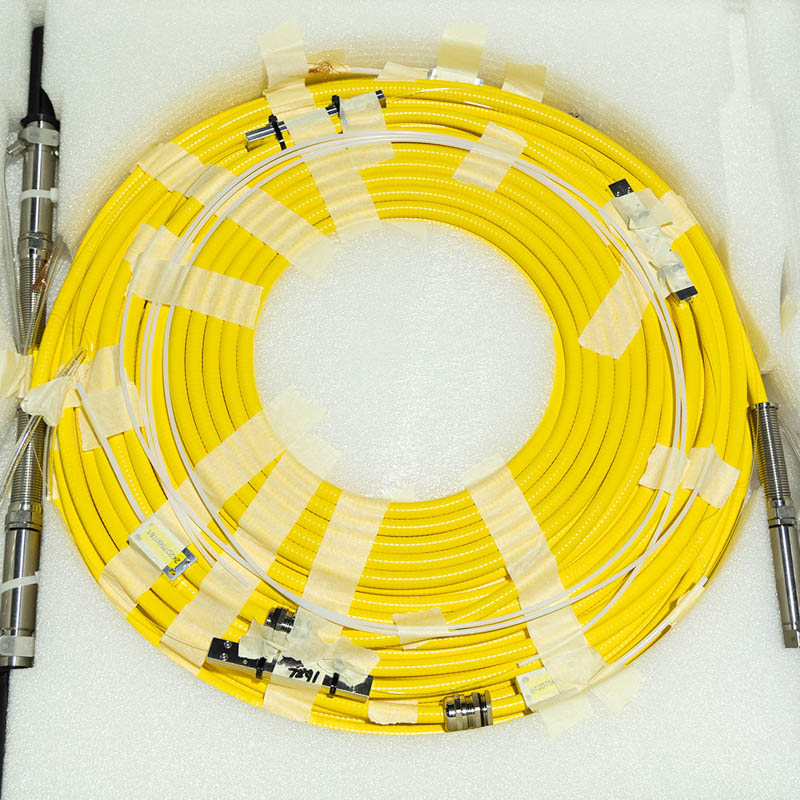

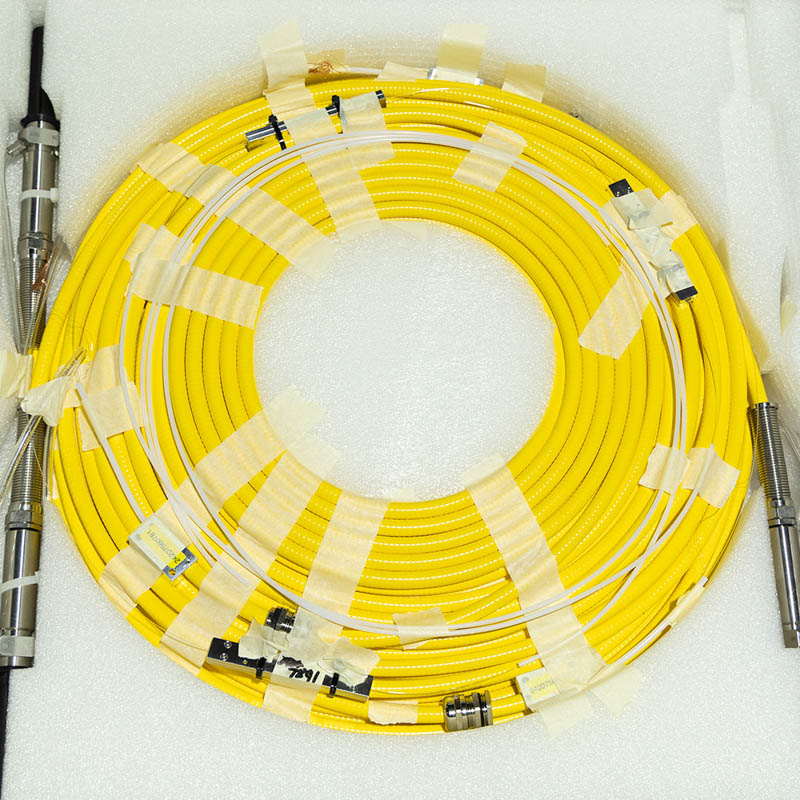

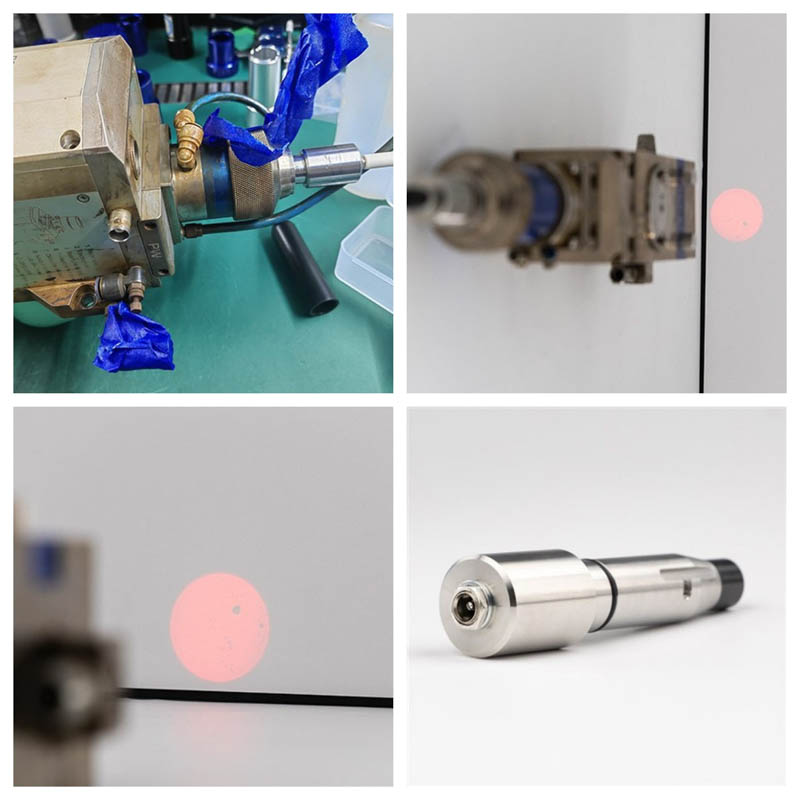

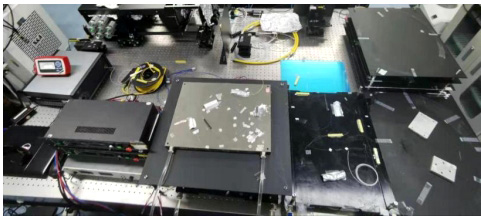

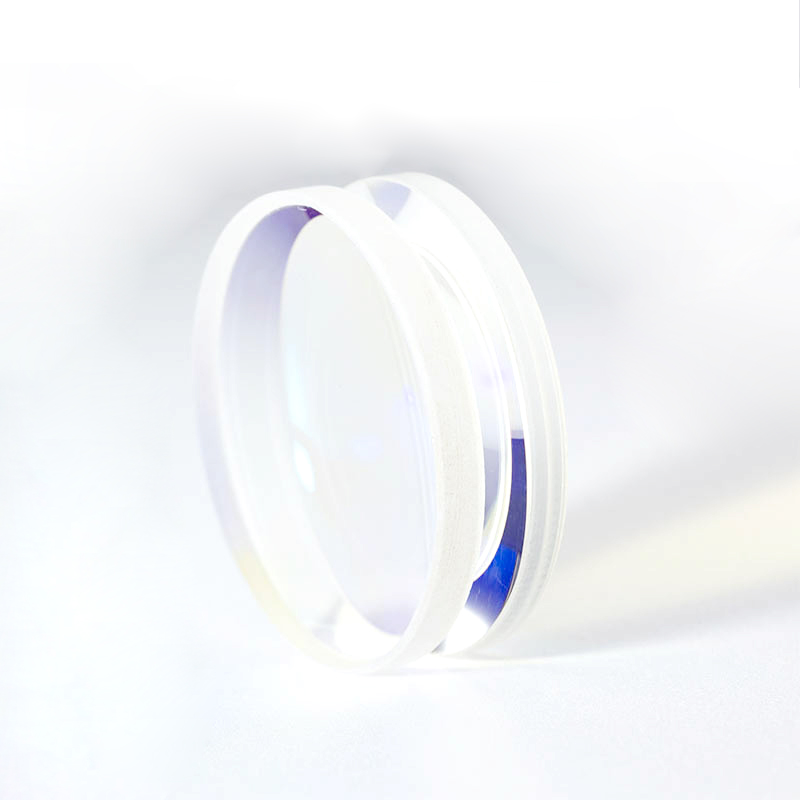

Image 3: Physical object image of the temperature measurement platform for the Raman fiber amplifier fiber core

Smart Design for Better Thermal Control

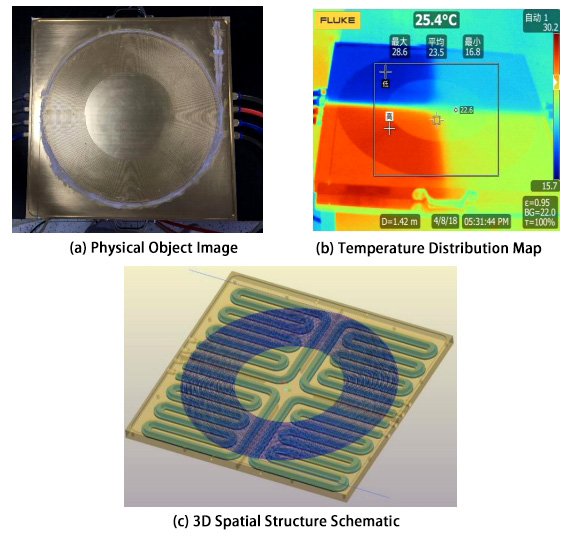

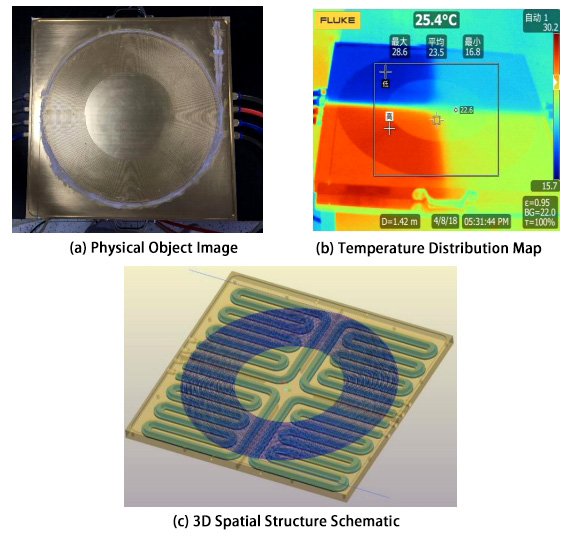

The study introduced a temperature-adjustable fiber plate that partitions and insulates heat along the fiber. Using this method:

Image 4: Schematic diagram of the temperature-adjustable fiber water-cooled plate

Practical Implications for Laser Manufacturers

This research offers practical tools for optimizing high-power fiber lasers:

-

Predict splicing quality using the newly proposed Splicing Thermal Factor (STF) model

-

Select appropriate pump configurations to minimize hot spots

-

Enhance output stability and quality through temperature control

Conclusion

Lou Zhaokai’s work lays a scientific foundation for managing fiber core temperature in real time—a game-changer for the safe and efficient operation of high-power fiber lasers. Whether you are in laser system design, manufacturing, or thermal simulation, these findings provide actionable insights that help push the limits of laser performance.